A water well pump is a vital component that transports water from underground to the surface, ensuring reliable access for drinking, irrigation, and industrial use․ This manual provides essential guidance on selecting, installing, and maintaining a water well pump system to optimize its performance and longevity․

What is a Water Well Pump?

A water well pump is a device used to extract water from an underground well or borehole; It operates by creating suction or pressure to draw water to the surface, ensuring a steady supply for residential, commercial, or agricultural needs․ Available in various types, such as submersible, jet, and hand pumps, these systems are tailored to different well depths and water requirements․ The pump is typically powered by an electric motor or, less commonly, a gasoline engine․ Its primary function is to transport water efficiently, making it an essential component of any well system․ Proper installation, maintenance, and operation are crucial to ensure reliable performance and longevity․ Understanding how a water well pump works is key to selecting the right model for specific needs and troubleshooting issues effectively․

Importance of a Water Well Pump Manual

A water well pump manual is an essential resource for anyone installing, operating, or maintaining a well pump system․ It provides detailed instructions for proper installation, wiring, and setup, ensuring the pump functions efficiently and safely․ The manual also outlines regular maintenance tasks, such as checking seals, lubricating parts, and monitoring performance, to prevent breakdowns and extend the pump’s lifespan․ Additionally, it serves as a troubleshooting guide, helping users identify and resolve common issues like low water pressure or electrical problems․ By following the manual’s guidelines, users can optimize their pump’s performance, reduce energy consumption, and ensure reliable water access․ It also highlights safety precautions to avoid accidents during installation and operation․ Ultimately, a well pump manual is a comprehensive guide that empowers users to manage their water well system effectively․

Types of Water Well Pumps

Water well pumps include submersible, jet, and hand pumps․ Submersible pumps are efficient and durable, operating underwater, while jet pumps are versatile for deep wells․ Hand pumps offer manual simplicity․

Submersible Pumps

Submersible pumps are highly efficient and durable, designed to operate entirely underwater․ These pumps are ideal for deep wells, offering a reliable solution for extracting water from significant depths․ They consist of a hermetically sealed motor connected to the pump body, which ensures minimal noise and maximum performance․ Submersible pumps are typically more energy-efficient compared to jet pumps, as they push water upwards rather than pulling it, reducing wear and tear․ They are widely used in residential, agricultural, and industrial settings․ Installation involves lowering the pump into the well casing, ensuring proper alignment and connection to the water system․ Regular maintenance, such as checking for sediment buildup and monitoring motor function, is essential to prolong their lifespan․ Their versatility and robust design make them a popular choice for modern water well systems․

Jet Pumps

Jet pumps are versatile and widely used for both shallow and deep wells, offering a reliable solution for water extraction․ Unlike submersible pumps, jet pumps are typically installed above ground, making them easier to access for maintenance and repairs․ These pumps operate by using a jet of water to create suction, drawing water from the well and pushing it to the surface․ Jet pumps are ideal for shallow wells (up to 50 feet deep) but can also handle deeper wells with the right configuration․ They are known for their simplicity, durability, and cost-effectiveness, making them a popular choice for residential and agricultural applications․ Jet pumps require regular maintenance, such as checking the impeller and suction line, to ensure optimal performance․ While they may not match the efficiency of submersible pumps for very deep wells, they remain a practical option for many water well systems․

Hand Pumps

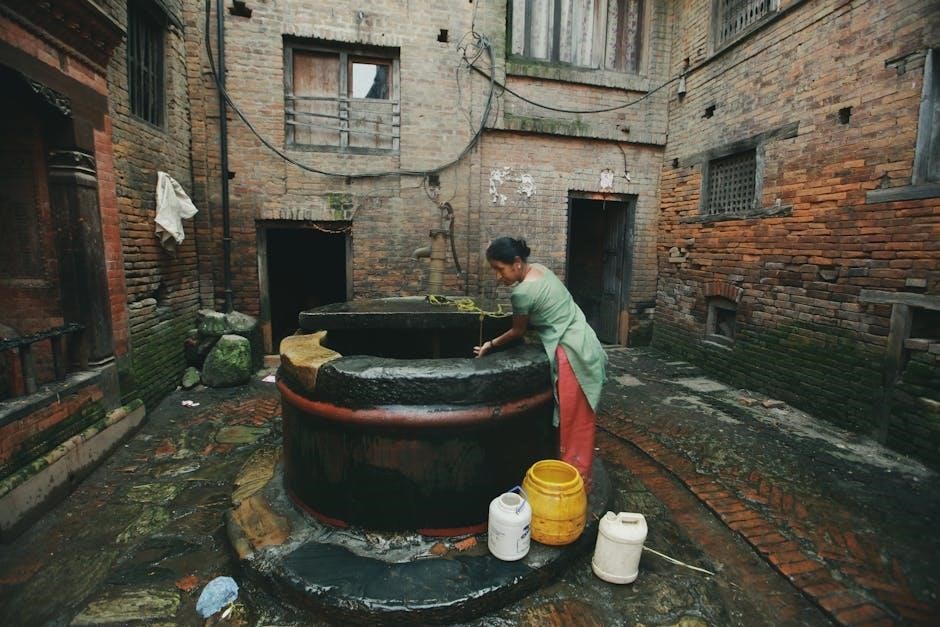

Hand pumps are a reliable and simple solution for accessing water from wells, especially in off-grid or emergency situations․ They operate manually, requiring no electricity, making them ideal for remote locations or as a backup system․ These pumps are typically installed at the wellhead and use a handle to create suction, drawing water from the well․ Hand pumps are suitable for shallow wells and are often used for small-scale water needs, such as watering animals or irrigating gardens․ They are also a cost-effective option for low-flow applications․ Maintenance is minimal, but regular checks are essential to ensure proper function․ For deeper wells, some hand pumps can be adapted with additional components, though their efficiency may decrease․ Overall, hand pumps offer a sustainable and durable way to access water, providing peace of mind during power outages or in areas without modern infrastructure․ They are a timeless choice for reliable water access․

Components of a Water Well Pump System

A water well pump system includes a pump, motor, controls, and accessories like valves and piping․ These components work together to ensure efficient water extraction and delivery․

Pump and Motor

The pump and motor are the heart of the water well system, responsible for extracting water from the well․ The pump is typically submerged in the well or mounted above ground, while the motor provides the power needed to create suction․ Submersible pumps are common for deep wells, offering high efficiency and reliability․ The motor is usually electric, though some systems may use gasoline engines․ Proper sizing of the pump and motor is crucial to match the well’s production capacity and water needs․ Regular maintenance, such as checking for worn parts and ensuring proper alignment, is essential to prolong their lifespan․ The pump and motor must be compatible with the well’s depth and water volume to ensure optimal performance and minimize wear․ Proper installation and alignment are also vital to prevent premature failure․

Controls and Switches

Controls and switches are essential for regulating the operation of a water well pump system․ The pressure switch is a critical component that monitors the system’s pressure, turning the pump on when water pressure drops and off when it reaches a set level․ This ensures a consistent water supply and protects the pump from continuous cycling․ The control box houses the electrical components, including relays and circuit breakers, which manage power distribution and protect the motor from overloads․ Float switches are also used in some systems, particularly in storage tanks, to regulate water levels and prevent overfilling or depletion․ Proper installation and adjustment of these controls are vital for efficient and safe operation․ Regular inspection of switches and controls ensures reliable performance and prevents unexpected system failures․

Accessories

Accessories play a crucial role in enhancing the functionality and efficiency of a water well pump system․ Foot valves, installed at the bottom of the well, prevent backflow and ensure the pump starts with water․ Check valves are essential to maintain prime and prevent water from flowing back into the well․ Pitless adapters allow for safe and convenient access to the pump without removing the well casing․ Pressure tanks store water under pressure, reducing the need for frequent pump cycling․ Additional accessories like water filters, pressure gauges, and wiring connectors ensure optimal performance and longevity․ Proper selection and installation of these components are vital for a reliable water supply․ Accessories should be chosen based on the specific needs of the well system and installed according to the manufacturer’s instructions․ Regular inspection and maintenance of these parts are key to avoiding system downtime․

Installation and Setup

Proper installation and setup of a water well pump ensure efficient operation and longevity․ Follow the manual for detailed steps, including wiring, priming, and testing the system thoroughly․

Steps for Installation

Proper installation of a water well pump ensures efficient operation and longevity․ Begin by turning off the electric pump and switching the curb valve to the manual setting․ Prime the pump by working the handle several times to draw water into the system․ Next, connect the pump to the main feed line and test the water flow at the spigot․ Ensure all connections are secure and properly sealed to prevent leaks․ If installing a submersible pump, carefully lower it into the well casing, ensuring it clears any obstructions․ For deep wells, consider professional assistance to avoid complications․ Finally, follow the manufacturer’s guidelines for electrical wiring and system setup․ Always refer to the user manual for specific instructions tailored to your pump model․ Proper installation is crucial for reliable water access and system durability․

Wiring and Electrical Setup

Proper wiring and electrical setup are critical for the safe and efficient operation of a water well pump․ Begin by ensuring the power supply is turned off before starting any work․ Refer to the wiring diagram provided in the user manual to connect the pump correctly․ The pump should be wired to a pressure switch, which regulates water pressure in the system․ Use a ground fault circuit interrupter (GFCI) outlet to enhance safety․ After completing the connections, turn the power on and test the system by running water through the spigot․ If the pump does not start, check the circuit breaker or connections for any issues․ Always follow local electrical codes and consider consulting a licensed electrician for complex setups․ Proper wiring ensures reliable operation and prevents potential hazards․ Regular checks and maintenance are essential to uphold system efficiency and safety․

Initial Setup and Testing

The initial setup and testing of a water well pump are crucial to ensure proper functionality and longevity․ Start by priming the pump according to the manufacturer’s instructions to remove any air from the system․ Turn off the electric pump and switch the curb valve to the manual pump if using a dual setup․ Work the handle several times to bring water to the surface․ Once water flows consistently, connect the pump to the house feed line․ Test the system by running water through a spigot to check for leaks or irregular pressure․ If water pulsates, it may indicate a waterlogged tank, requiring replacement․ Regularly inspect the pump and motor for wear and tear․ Proper initial setup ensures efficient operation and helps identify potential issues early․ Always refer to the user manual for specific instructions tailored to your pump model․

Maintenance and Troubleshooting

Regular maintenance ensures the longevity and efficiency of your water well pump․ Inspect for wear, address leaks promptly, and check pressure settings to prevent system overload․

Regular Maintenance Tasks

Regular maintenance is crucial for the efficient operation of a water well pump system․ Start by inspecting the pump and motor for signs of wear or corrosion․ Check the pressure switch and pressure tank to ensure they are functioning correctly․ Inspect the well casing for any cracks or damage that could allow contaminants into the water supply․ Monitor the water flow rate and pressure to detect potential issues early․ Lubricate moving parts and replace worn-out seals or O-rings to prevent leaks․ Additionally, test the water quality regularly to ensure it remains safe for use․ Keep the area around the well clean to prevent debris from entering the system․ By following these maintenance tasks, you can extend the lifespan of your pump and ensure reliable water supply․ Always refer to the user manual for specific maintenance recommendations tailored to your pump model․

Troubleshooting Common Issues

When dealing with a water well pump, common issues can arise that require prompt attention․ Low water pressure may indicate a malfunctioning pressure switch or a failing pump․ If the pump does not start, check for electrical issues such as blown fuses or tripped breakers․ Excessive noise could signal worn or damaged internal components․ Water leakage often points to faulty seals or connections․ If the pump runs continuously, it may be overworking due to a malfunctioning pressure tank or incorrect settings․ For each issue, consult the user manual for diagnostic steps․ Regular testing of the system, including the pressure switch and tank, can help identify problems early․ If unresolved, contact a professional to ensure proper repair and maintain system efficiency․

Advanced Diagnostic Techniques

For complex issues, advanced diagnostic techniques can help pinpoint problems in your water well pump system․ Pressure testing involves measuring pressure at various points to identify drops or leaks․ Flow rate analysis checks if the pump delivers the expected water volume, revealing issues like clogged screens or worn impellers․ Electrical testing with a multimeter can identify faults in wiring, motors, or control boxes․ Thermal imaging detects overheating components, a sign of impending failure․ Vibration analysis can reveal imbalances or misalignments in the pump․ For deep wells, downhole camera inspections allow visual examination of the pump and casing․ If issues persist, professional diagnostic services may be necessary to ensure accurate assessments and repairs․ Regular use of these techniques ensures optimal performance and extends the lifespan of your water well pump system․

Safety Precautions and Best Practices

Sanitize your well and pump system regularly to prevent contamination․ Ensure proper electrical connections to avoid hazards․ Schedule annual professional inspections for optimal safety and efficiency․

Precautions During Installation and Use

When installing a water well pump, always follow the manufacturer’s manual to ensure safety and proper setup․ Turn off the power supply before performing any maintenance or repairs․ Use appropriate personal protective equipment, such as gloves and safety glasses, to prevent injuries․ Regularly inspect electrical connections to avoid short circuits or fires․ Ensure the well casing is secure and properly sealed to prevent contamination․ Never attempt to repair or modify the pump without the necessary expertise, as this can lead to system failure or water quality issues․ Additionally, keep the area around the pump clean and clear of debris to maintain efficiency․ Following these precautions helps protect both the pump and the user, ensuring reliable water supply for years to come․

Best Practices for Longevity and Efficiency

To ensure your water well pump operates efficiently and lasts longer, adopt several best practices․ Regularly schedule maintenance to inspect and clean filters, check pressure switches, and verify valve functionality․ Ensure electrical connections are secure and meet local safety codes to prevent malfunctions․ Monitor water usage patterns to avoid overworking the pump, which can lead to premature wear․ Periodically test water quality to identify potential contaminants that may affect pump performance․ During seasonal changes, prepare the system for extreme temperatures, such as winterizing to prevent freezing․ Keep the surrounding area clean and clear of debris to maintain proper airflow and accessibility․ By following these practices, you can optimize your pump’s efficiency, reduce energy consumption, and extend its lifespan while ensuring consistent water supply․ Regular monitoring and timely interventions are key to maintaining a reliable system․

This guide provides essential insights into water well pumps, from installation to maintenance․ For further learning, visit Water Pumps Direct or watch Wranglerstar’s YouTube tutorials․

A water well pump is a crucial system component, ensuring water supply for various needs․ Proper installation, regular maintenance, and troubleshooting are essential for longevity and efficiency․ Always follow the manual, inspect components like o-rings and valves, and address issues promptly․ Consider upgrading to solar or hand pumps for sustainability․ For deeper wells, professional advice is recommended․ Stay informed through resources like Water Pumps Direct and YouTube tutorials․ Regularly test water quality and system performance to ensure reliability․ Invest in a water test kit and maintain your pump system to avoid costly repairs․ By adhering to these tips, you can enjoy a consistent and reliable water supply․

Additional Resources for Further Reading

For in-depth knowledge, explore resources like Water Pumps Direct, offering guides on installation and troubleshooting․ Wranglerstar’s YouTube channel provides practical demonstrations, such as the Simple Pump installation․ Manuals for submersible pumps and pressure tanks are available for download, ensuring you have detailed instructions․ Websites specializing in water well systems share step-by-step troubleshooting techniques and maintenance tips․ Additionally, educational materials like “English Reader in Artificial Intelligence” and construction-focused texts offer broader insights․ These resources help you understand system components, diagnostic methods, and best practices for optimal pump performance․ Utilize these materials to enhance your understanding and ensure your water well system operates efficiently and effectively․

Future Trends in Pump Technology

The future of water well pump technology is poised for significant advancements, focusing on sustainability, efficiency, and smart integration․ Solar-powered pumps are gaining traction, offering eco-friendly solutions for remote and off-grid wells․ Additionally, advancements in materials science are leading to more durable and corrosion-resistant components, extending pump lifespans․ Smart pump systems, equipped with IoT capabilities, will enable real-time monitoring and automated adjustments, optimizing water usage and energy consumption․ These systems can predict maintenance needs, reducing downtime and improving overall performance․ Furthermore, the development of variable-speed motors and advanced control algorithms will enhance efficiency, lowering operational costs․ As technology evolves, water well pumps will become more integrated with renewable energy sources and intelligent systems, ensuring reliable and sustainable water access for years to come․ These innovations promise to revolutionize the industry, making water well systems more efficient and environmentally friendly․